FOR YOUR NEW SMILE-CREATION IN THE BACKSTAGE

Josip Pecevski, dental technician

Private dental laboratory practice

˝Josip Pecevski˝

Ulica grada Chicago 25, 10 000 Zagreb

info@dentique-lab.com

As a patient, have you ever wondered who puts the stamp on your smile? Most people have encountered, not once but more than once, the creation of prosthetic work (crowns, bridges, dentures, veneers, etc.). So, after you decided to do something to improve your oral health and beautify your smile, you bravely came to the dentist, sat down in the chair, talked about all your problems and, of course, expressed your wishes. After your doctor has finished repairing the existing state of fillings, treatment, perhaps tooth extraction and grinding in preparation for future prosthetic work, the impression or scanning phase follows, after which we come to the process of trying on the work that will ultimately adorn your smile. But is it all as simple as it seems at first? Many doctors would disagree and they would be right. Although it looks simple, these are complex interventions in which the result would be missing without teamwork. Which means that neither the patient, nor the doctor, nor the technician would be satisfied. The quality of service and the possibility of providing more services are far greater than 15 years ago! The changes taking place in the digitization system have not bypassed our profession either, both in the practice area and in the laboratories of dental technology.

Today, it is unthinkable that prosthetic work planned in the office is not accompanied by the dental laboratory with its laboratory planning of prosthetic work. The processes between the doctor’s office and the laboratory are rarely known to the patient, but they become more and more complex every year because the digital world of technology is developing at an unprecedented speed, so our results are becoming better, more modern, more precise and more beautiful. But in order to meet all the criteria, close contact between the doctor’s office and the laboratory is necessary, and they must be persistent. At the same time, we must not forget the patient and his cooperation, both with the doctor’s office and with the technician in almost all phases of making a prosthetic prosthesis.

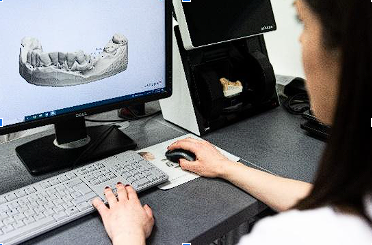

In today’s era, when intraoral scanners, dslr cameras, software for planning and designing, and printers and milling machines are at our disposal, the processes in the laboratory are far more complex and “turned upside down”, and that is how one of the most famous processes for the production of prosthetic aids, called Backward planning”, which implies that we first start with the digital planning of what we want to get in the end, and only then do we start with the stages of making a prosthetic replacement.

Therefore, every team (office and laboratory) that advocates backward planning must first receive a digital or physical impression of both jaws of the patient of the situation in which we found the patient, so before any grinding or extraction. If the team has a face scanner, it is also desirable to receive a digital print of the smiling face of the patient. Also, at the same time, high-quality photo documentation must be created so that the laboratory can have an insight at any time and an additional option for comparison in addition to prints of situations.

If at least 2 of the 3 necessary information mentioned above (situation print, digital facial print, photo documentation) have been created, with the fact that the situation print is mandatory, the laboratory can access the analysis of the situation and consultations with the doctor in charge of the work. At the consultation between the laboratory and the doctor’s office, several solutions must be created so that the patient can have a wider choice, taking into account the patient’s health and financial capabilities.

After deciding which type of prosthetic replacement will be provided to the patient, the dental technician in the laboratory at the design department digitally plans the aesthetic and morphological appearance of the final work and creates the first type of prototype called wax up. In this process, the designer chooses the design and morphology of the tooth that would be functionally most optimal for the patient in the received state. When choosing the most optimal appearance and design, things like the biological width of natural teeth, the biological width of the gingival arches, the position of each individual tooth that will carry the future work must be taken into account, we also need to take into account where we want these carrier teeth later in the end in order to obtain, we take into account the length of the teeth that we want to have in relation to the patient’s lips and compare them with the width of the gingival arches in order to achieve the most harmonious relationship between the width and length of the teeth. We take into account the relationship between the two jaws and the teeth in them, their position and height. We also look at the position of the lips at rest, a gentle and broad smile, and the profile features of the face. After the design and print of the wax up, the doctor transfers the wax up into the mouth and imitates the planned design directly in the mouth with the help of a material that, like a thin facade, shows the patient live what it should look like, the technician also prepares a photo representation of how the patient should look with a future smile.

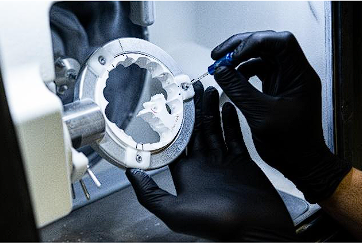

If everything went well and the patient likes the results, the doctor starts preparing the patient for work. Grinding is done on the basis of the designed wax up. After the impression of the polished situation, the technician in the laboratory begins with the digital design of another prototype made of PMMA or composite, which will serve primarily as temporary teeth while the patient waits for his final work, and secondarily as a test for the impression of the polished situation in order to make sure that the impression is precise enough for creation of the final work. If we have successfully passed that stage, the technician continues to design the construction on the ground blocks and the printed gingiva, which will carry the final work and its production, depending on which material was chosen as the basis of the construction. If metal or composite is chosen as the base of the construction, they are produced by 3D printing. If zircon, lithium-disilicate or PMMA was chosen as the base of the construction, then the constructions are milled with the help of CNC machines.

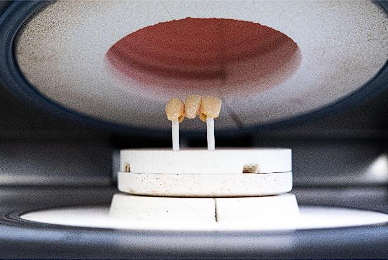

After the construction is made and when the technician processes it and prepares it for layering the aesthetic material, the technician takes over the work on the aesthetic suit and with the help of dental ceramics or composites, materials that have been profiled as the main aesthetic materials, the technician forms the aesthetic material into the shape of the tooth as agreed with with a patient at the wax up stage. The most difficult thing in this process, which is also one of the most demanding in the laboratory, is to reproduce the color of those teeth so that the prosthetic work looks natural. A number of factors play a key role in obtaining a satisfactory color, such as the selection of materials for the construction, the color of the ramus under the structure, the size of the ramus under the structure, the thickness of the structure, the selection of aesthetic material and the color of the remaining teeth in the patient’s jaw that are not covered by prosthetic therapy. The goal is to obtain natural gradation of color by layers from the deep dentine layers to the surface enamel layers, natural fluorescence and transparency as natural teeth have, and satisfactory fullness of color and brightness.

Each of the mentioned processes consists of more detailed sub-processes in order to complete each process successfully, because top-quality work can only be achieved by setting up and repeating the process, and it is necessary that each person involved in the therapy knows the subject they are dealing with and that all criteria are met in order for the work to be successful. from beginning to end brought to perfection created by nature.